professional factory provide Alloy Steel 33H 45H Socket Set Screws Export to Mombasa

Short Description:

Alloy Steel 33H 45H Set Screws Grub Screws Metric Size: M1.4 – M52, Inch Size: 0# – 2″ Hexagon Socket(Allen), Torx Star, Square, Slotted Drive Types Flat Point, Cup Point, Cone Point, Dog Point Other Drive and Point Type are also available acc. to customer requirement Various Surface Finishes Various Material Grades are available Please feel free to contact us for more details

Product Detail

Product Tags

professional factory provide Alloy Steel 33H 45H Socket Set Screws Export to Mombasa Detail:

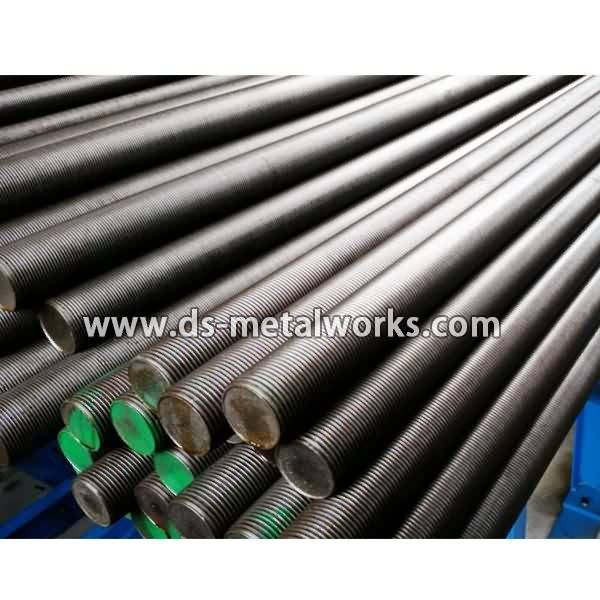

Alloy Steel 33H 45H Set Screws Grub Screws

Metric Size: M1.4 – M52, Inch Size: 0# – 2″

Hexagon Socket(Allen), Torx Star, Square, Slotted Drive Types

Flat Point, Cup Point, Cone Point, Dog Point

Other Drive and Point Type are also available acc. to customer requirement

Various Surface Finishes

Various Material Grades are available

Please feel free to contact us for more details

Product detail pictures:

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We're ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for professional factory provide Alloy Steel 33H 45H Socket Set Screws Export to Mombasa, The product will supply to all over the world, such as: Portugal, Sierra Leone, Nairobi, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of Standing in Domestic Markets, Walking into International Markets. We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Scotty Kilmer, mechanic for the last 46 years, shows how you can remove those stuck nuts and bolts when working on your car. Don’t blow your head gasket trying to remove them, just use a little heat as this video shows. And, If you like my car help, be sure to watch my live car talk show every Saturday morning at 10 AM CST on YouTube. I answer your car questions LIVE there. Just check it out at https://www.youtube.com/watch?v=VognjkYaMjg&list=UUuxpxCCevIlF-k-K5YU8XPA&feature=c4-overview . And remember, every TUESDAY I upload a new video, so don’t miss them.

China Far Eastern Industry Co.,Ltd located in weifang city . We engage into designing, developing , testing, manufacturing, repairing and drilling service.

Our business scope embraces:

1. Rock Bit ( TCI tricone bit, steel tooth bit,PDC bit,DTH bit ).

2. Drilling Equipment (stabilizer,drill pipe,drill collar,ESP pump).

3. Drilling Tools (drill pipe tong, roller kelly bushing,hydraulic cathead,kelly spinner,master bushing and accessories,penumatic spinning wrenches, rotary slip, safety clamp,slip type elevator ,tong dies and inserts).

4. Drill Rig and Parts (conventional drilling rig,trailer mounted & skidding type drilling rig,truck mounted drilling workover rig,top driver,swivel,rotary table,drilling motor,crown block and sheaves ,travelling blocks and hooks).

5. Mud Pump and Parts (BH-800III Imud pump ,F-500/800/1000/1300/1600,ZB-400II,hydraulic cylinder,liner).

6. Solid Control Equipments (balanced elliptical shale shaker,centrifuger,JYQ liquid-gas separator,JZCQ new type vacuum degasser ,mud cleaner).

7. Wellcontrol Equipments (BOP closing unit and control ,BOP handling equipment,BOP stack,manifold,wellhead and X-MAS tree and other requirement related petroleum).

8.Rock Drilling Machinery (Air Leg Rock Dril,Drill Rod & DTH Hammer,Hydraulic Breaking Hammer)

Our products are according as API standard and we have obtained ISO9001:2000 certificated.We are exporting to more than 20 countries and regions.Our target is to supply our products with “QUALITY FIRST, PRICE COMPETITIVE ,SERVICE BEST” and spread company culture to all over the world. welcome all friends to visit our factory.

www.chinafareastern.com www.cnfareastern.com