System HR Structural Nuts Price - ASTM A193 B7 All Threaded Rods Threaded Bars – Dingshen Metalworks

Short Description:

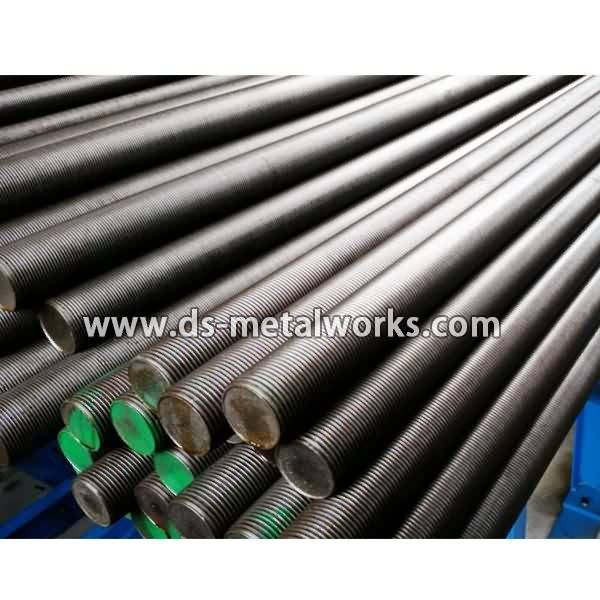

ASTM A193/A193M B7 All Threaded Rods All Threaded Bars API Flange Valve Wellhead All Thread Stud Bolts Alloy steel bolting for pressure vessels, valves, flanges, and fittings for high temperature or high pressure service, or other special purpose applications. Standard: IFI-136, DIN975 Inch Size: 1/4”-4” with various lengths Metric Size: M6-M100 with various lengths Other Available Grade: ASTM A193/A193M B7, B7M, B16 B8 Class 1 & 2, B8M Class 1 & 2, ASTM A320/A320M L7, L7M, L43, B8 Cl...

Product Detail

Product Tags

System HR Structural Nuts Price - ASTM A193 B7 All Threaded Rods Threaded Bars – Dingshen Metalworks Detail:

ASTM A193/A193M B7 All Threaded Rods All Threaded Bars

API Flange Valve Wellhead All Thread Stud Bolts

Alloy steel bolting for pressure vessels, valves, flanges, and fittings for high temperature or high pressure service, or other special purpose applications.

Standard: IFI-136, DIN975

Inch Size: 1/4”-4” with various lengths

Metric Size: M6-M100 with various lengths

Other Available Grade:

ASTM A193/A193M B7, B7M, B16 B8 Class 1 & 2, B8M Class 1 & 2,

ASTM A320/A320M L7, L7M, L43, B8 Class 1 & 2, B8M Class 1 & 2, and so on.

Finish: Plain, Black Oxide, Zinc Plated, Zinc Nickel Plated, Cadmium Plated, PTFE etc.

Packing: Bulk about 25 kgs each carton, 36 cartons each pallet

Advantage: High Quality and Strict Quality Control, Competitive Price,Timely Delivery; Technical Support, Supply Test Reports

Please feel free to contact us for more details.

Product detail pictures:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for System HR Structural Nuts Price - ASTM A193 B7 All Threaded Rods Threaded Bars – Dingshen Metalworks, The product will supply to all over the world, such as: Southampton, USA, Slovak Republic, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

https://www.jm-industry.com

Standard: ASME/ANSI B 18.2.1

Size: 1/2”-3”

Material: Carbon Steel, Alloy Steel, Stainless Steel, Brass

Grade: ASTM A325, A490,A354 Gr. BC ; A307 Gr. B

Thread: M, UNC, UNF

Finish: Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G

https://GoRambling.com

Discover more free ideas at my website today ![]()

My wife and I are planning on building a vertical log cabin, often referred to as a stockade style log cabin. Here are some pictures to give you an idea. Here’s one…here’s another, and here you go.

Anyway we’ll be moving to Alaska, probably near the Kenai Peninsula or Matanuska Valley. Of course we’re going to try and avoid permafrost, but who knows exactly what kind of land we’ll buy.

Our vertical log cabin in Alaska will be constructed on concrete posts that’ll be poured into Sonotubes that are buried below the frost line (probably around 40 to 50 inches underground).

And then the posts will come up about 18 inches into the air…at which point we’ll begin the cabin. So yes, the cabin will be raised about 18 inches off the ground.

Anyway, I have no experience to build anything of this magnitude, but this doesn’t scare me. My wife and I look forward to the challenge. So needless to say, I have a lot of questions, lots more research to do, and plenty of planning that awaits us.

I’m posting this video to present my plan for the concrete posts and the insulated floor that will sit atop these 10 concrete posts.

First, here is my rough sketch for our small vertical log cabin. It’s 10 feet by 35 feet. I’ve kind of modeled it after an RV, so I call it our RV cabin. It seems like it’ll be a nice comfortable cabin that will serve us well. And it seems like it’ll be somewhat easier to build than other plans.

Anyway, I’ll make another video later on and go over the interior and how everything will be laid out.

Okay…so here is my plan for the concrete posts and the insulated cabin floor.

1)The grass (or the ground). We’ll start by clearing the ground and marking off the perimeter of the cabin, making sure the 90 degree angles are correct.

2)We’ll dig our holes for the concrete posts and fill the bottoms with about 6 to 12 inches of gravel.

3)Then we’ll insert our Bigfoot footing that has

4)…the 12 to 18 inch diameter cardboard Sonotube, and then will fill them both with concrete.

5)We’ll make sure to insert 3 rebar bars before the pouring. What size rebar is best? Thoughts?

6)The sill bolt will go into the Sonotube before pouring and the bolt will stick out about 6-12 inches.

So after we pour the concrete, we go on to…

7)This is the part I’m a little unsure about it. Should we put down some kind of thick plastic sheeting that will be directly in contact with the elements, or should we apply some kind of coating to #8, the bottom subfloor)? Would polyurethane work?

8)So the bottom subfloor will be hooked onto the sill bolts. I’m guessing we should drill a hole in the bottom subfloor sheet of wood, and then just hook the board to all of the sill bolts. Right?

9)This sill log will be a 3-sided log (here’s a picture) And we’ll mill this sill log with an Alaskan saw mill…which is an attachment to a chainsaw.

10)So here we’ll put in the floor joists by attaching them to the sill log by means of a gain and tenon fit. And then we’ll put in the insulation.

11)Here we’ll nail on the top subfloor. Should we put any kind of coating on this? Polyurethane?

So after we erect the vertical logs complete with the roof, we’ll add #12, the carpet.

Okay? So what do you think? Please don’t be shy about your critique! I can handle constructive criticisms! Thanks a lot and please leave a comment if you have any thoughts about our plan.

Thanks!